Xeikon has optimised its digital press solutions with multiple installations of Meech’s CyClean™ non-contact web cleaning systems. Ideal for high speed presses and with an ability to handle virtually any substrate, CyClean ensures spotless webs are maintained on the Xeikon 3050 and Xeikon 3500 presses, part of the company’s 3000 series used for wall paper production and folding carton applications.

Founded in 1988, Xeikon has established itself as an innovator in digital printing technology. The company is committed to delivering high quality web-fed digital colour presses to a number of sectors – such as label, packaging and commercial print – which are sold worldwide through a value-added distributor network.

“When speaking to prospective customers, we would often hear printers comment on the amount of dust present on their printing presses as a result of the production environment they operate in,” explains Filip Weymans, Director of Segment Marketing for Labels and Packaging at Xeikon. “With end product quality being heavily scrutinised, it is imperative to ensure that our presses remain spotless. For this reason, we saw an opportunity to optimise our offering by implementing an automated solution that would guarantee the web’s cleanliness, plus reduce operator maintenance.”

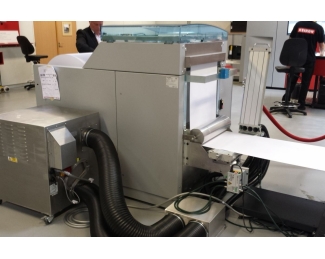

This has led to the installation of a number of Meech’s CyClean web cleaners over the past two years. CyClean is a compact, non-contact, double-sided blow and vacuum-based system which flows contaminants into an inline filter unit. It can clean webs up to 3m in width, is capable of removing 0.5 micron contaminants and has a small footprint that enables it to be fitted into confined spaces.

Its compact size makes CyClean ideal for installation on the Print Machine Supply unwinder of the Xeikon 3050 and Xeikon 3500 roll-fed digital presses. As the web is unwound from the roll, it is passed through the web cleaner before it enters the digital press.

Integrated static control on the entry and exit of the cleaning head guarantees a thorough, long-lasting cleaning process. The in-built AC ionising bars neutralise all static charges on the web and ensure easy breakdown of the bonds holding contaminants to it. The risk of re-attracting contaminants to the cleaned web surfaces is also significantly reduced.

“We sell Meech’s web cleaners with our presses as part of an optional package,” says Filip. “It optimises the overall production process and we strongly recommend the CyClean’s inclusion in all of our sales, as it adds significant value.”

Filip is also keen to comment on the partnership with Meech, who has gone on to become an Aura Partner for Xeikon since the CyClean installations. “The Aura Partner Network is a robust and fully encompassing group based on non-exclusive relationships with industry-leading partners,” he explains. “Meech has been extremely supportive in helping to explain to customers the importance of having a clean web in the print industry. We’ve been able to do this by running test trials and demonstrations at networking events, such as Xeikon Café.”

Last hosted in Antwerp, Belgium in March 2015, Xeikon Café functioned as an informal knowledge exchange platform, where guests could discuss trends affecting the print, packaging and converting sectors. During the event, Meech explained to visitors how web cleaning could minimise wastage and achieve higher levels of productivity on digital print applications, as well as highlighting a move towards non-contact systems, such as CyClean, in the label market.

Filip concludes: “Thanks to CyClean, we are in a position where we can sell our presses in full knowledge that the customer will not have to worry about the presence of contamination on the web. We are more than happy with the system, not to mention the service and support provided by Meech.”